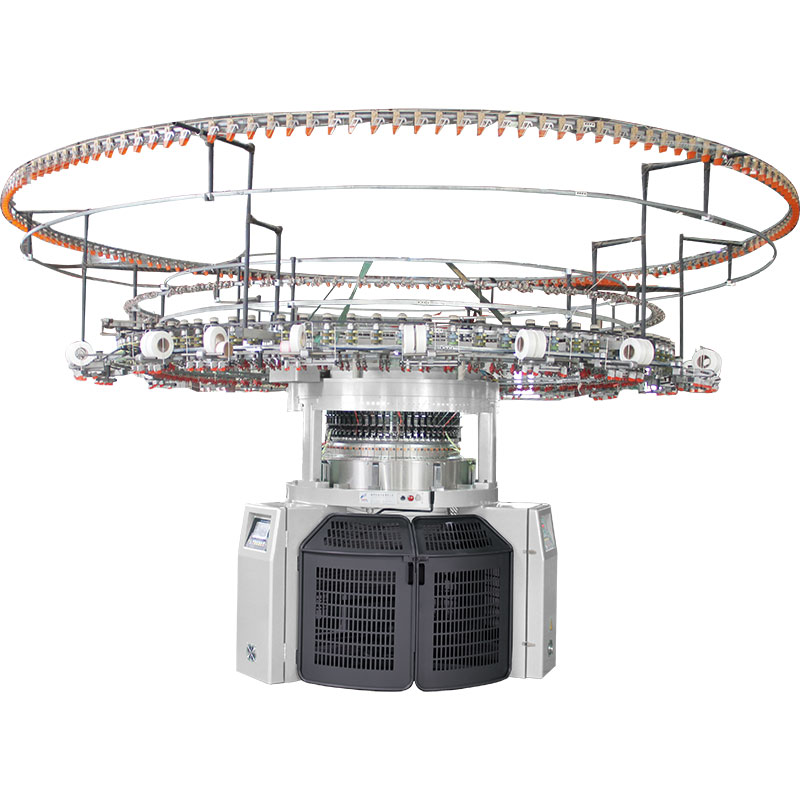

Cover Polyster Well Fleece Machine - High Production Terry Knitting Machine – Morton

Cover Polyster Well Fleece Machine - High Production Terry Knitting Machine – Morton Detail:

| MODEL | DIAMETER | GAUGE | FEEDER |

| MT-TY2.0 | 30″-38″ | 16G–24G | 60F-76F |

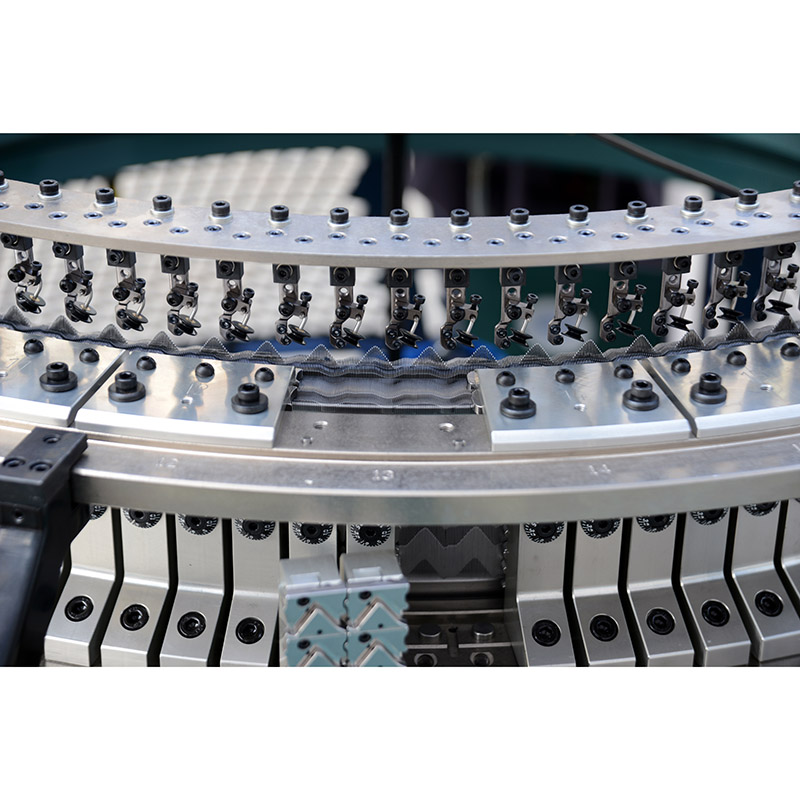

Machine Features:

1 Suspended Wire Race Bearing Design enable the machine improving running precision and ruducing impact resistance.

At the same time, the drive energy consumption is greatly reduced.

2 Using aircraft aluminum aolly on main part of machine to improve heat dissipation performance

and reduce force deformation of the cam box.

3 One Stitch Adjustment to replace the visual error of the human eye with machining accuracy,

and the accurate scale display with the high-precision Archimedean adjustment makes the

replication process of the same cloth on different machines simple and easy.

4 Unique machine body structure design breaks through traditional thinking and improves machine stability.

5 With central stitch system, higher accuracy, simpler structure, more convenient operation.

6 New sinker plate fixing design,eliminating deformation of sinker plate.

Morton Single Terry Machine Interchange Series can be interchanged to single and three-thread fleece machine by replacing the conversion kit.

Product detail pictures:

Related Product Guide:

Generally customer-oriented, and it's our ultimate goal for being not only the most trusted, trustable and honest provider, but also the partner for our customers for Cover Polyster Well Fleece Machine - High Production Terry Knitting Machine – Morton , The product will supply to all over the world, such as: Kyrgyzstan, Italy, Mombasa, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.