Electronic Jacquard Double Jersey 2 Way System - High Production Terry Knitting Machine – Morton

Electronic Jacquard Double Jersey 2 Way System - High Production Terry Knitting Machine – Morton Detail:

| MODEL | DIAMETER | GAUGE | FEEDER |

| MT-TY2.0 | 30″-38″ | 16G–24G | 60F-76F |

Machine Features:

1 Suspended Wire Race Bearing Design enable the machine improving running precision and ruducing impact resistance.

At the same time, the drive energy consumption is greatly reduced.

2 Using aircraft aluminum aolly on main part of machine to improve heat dissipation performance

and reduce force deformation of the cam box.

3 One Stitch Adjustment to replace the visual error of the human eye with machining accuracy,

and the accurate scale display with the high-precision Archimedean adjustment makes the

replication process of the same cloth on different machines simple and easy.

4 Unique machine body structure design breaks through traditional thinking and improves machine stability.

5 With central stitch system, higher accuracy, simpler structure, more convenient operation.

6 New sinker plate fixing design,eliminating deformation of sinker plate.

Morton Single Terry Machine Interchange Series can be interchanged to single and three-thread fleece machine by replacing the conversion kit.

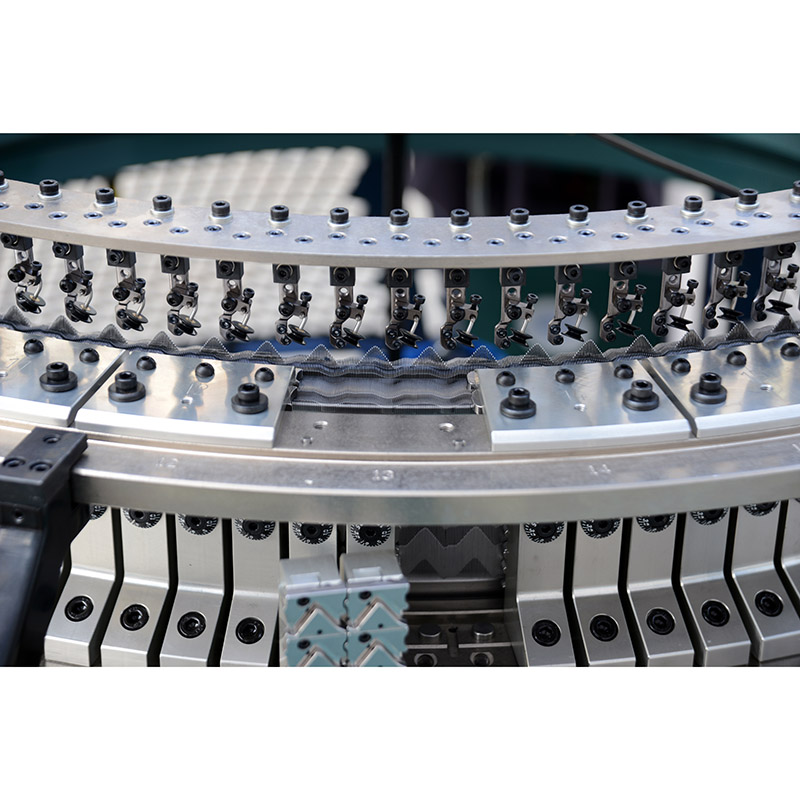

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs of Electronic Jacquard Double Jersey 2 Way System - High Production Terry Knitting Machine – Morton , The product will supply to all over the world, such as: Anguilla, Berlin, Jordan, All the employees in factory, store, and office are struggling for one common goal to provide better quality and service. Real business is to get win-win situation. We would like to provide more support for customers. Welcome all nice buyers to communicate details of our products with us!

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.