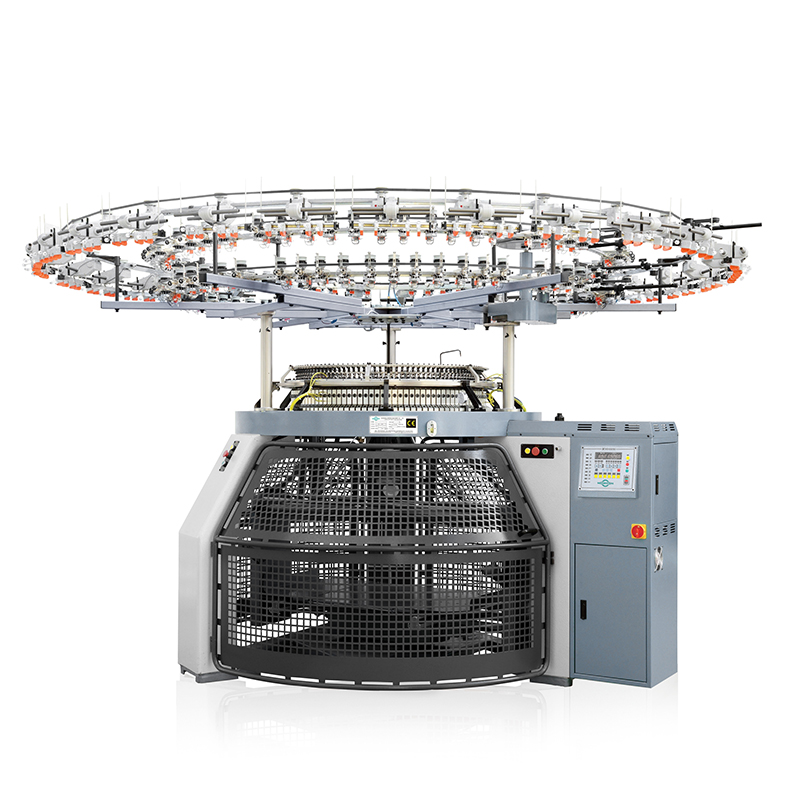

Factory Supply China Factory Supplied Reverse Terry Knitting Machine

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of Factory Supply China Factory Supplied Reverse Terry Knitting Machine, Your inquiry might be extremely welcomed plus a win-win prosperous development are what we’ve been expecting.

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of China Reverse Terry Knitting Machine, Our factory covers an area of 12,000 square meters, and has a staff of 200 people, among which there are 5 technical executives. We are specialized in producing.We have rich experience in export. Welcome to contact us and your enquiry will be replied as soon as possible.

| MODEL | DIAMETER | GAUGE | FEEDER |

| MT-EC-RT2.0 | 30″-38″ | 16G–24G | 60F-76F |

Machine Features:

1. Suspended Wire Race Bearing Design enable the machine improving running precision and ruducing impact resistance.

At the same time, the drive energy consumption is greatly reduced.

2. Using aircraft aluminum aolly on main part of machine to improve heat dissipation performance and reduce force deformation of the cam box.

3. One Stitch Adjustment to replace the visual error of the human eye with machining accuracy, and the accurate scale display with the high-precision Archimedean adjustment makes the replication process of the same cloth on different machines simple and easy.

4. Unique machine body structure design breaks through traditional thinking and improves machine stability.

5. With central stitch system, higher accuracy, simpler structure, more convenient operation.

6. New sinker plate fixing design,eliminating deformation of sinker plate.Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of Factory Supply China Factory Supplied Reverse Terry Knitting Machine, Your inquiry might be extremely welcomed plus a win-win prosperous development are what we’ve been expecting.

Factory Supply China Reverse Terry Knitting Machine, Our factory covers an area of 12,000 square meters, and has a staff of 200 people, among which there are 5 technical executives. We are specialized in producing.We have rich experience in export. Welcome to contact us and your enquiry will be replied as soon as possible.