High Loop Pile Knitting Machine - High Production Terry Knitting Machine – Morton

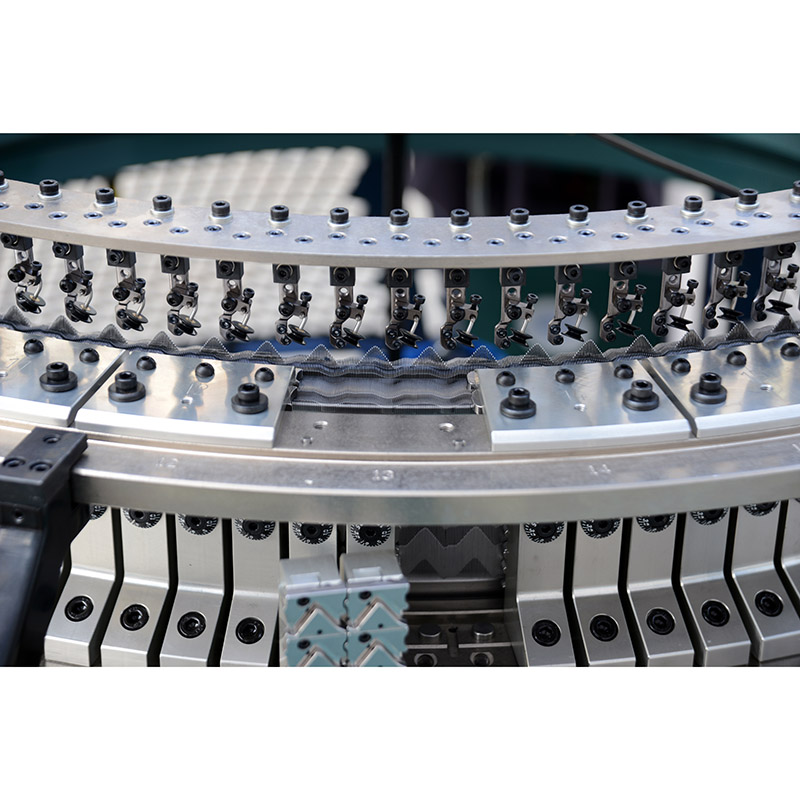

High Loop Pile Knitting Machine - High Production Terry Knitting Machine – Morton Detail:

| MODEL | DIAMETER | GAUGE | FEEDER |

| MT-TY2.0 | 30″-38″ | 16G–24G | 60F-76F |

Machine Features:

1 Suspended Wire Race Bearing Design enable the machine improving running precision and ruducing impact resistance.

At the same time, the drive energy consumption is greatly reduced.

2 Using aircraft aluminum aolly on main part of machine to improve heat dissipation performance

and reduce force deformation of the cam box.

3 One Stitch Adjustment to replace the visual error of the human eye with machining accuracy,

and the accurate scale display with the high-precision Archimedean adjustment makes the

replication process of the same cloth on different machines simple and easy.

4 Unique machine body structure design breaks through traditional thinking and improves machine stability.

5 With central stitch system, higher accuracy, simpler structure, more convenient operation.

6 New sinker plate fixing design,eliminating deformation of sinker plate.

Morton Single Terry Machine Interchange Series can be interchanged to single and three-thread fleece machine by replacing the conversion kit.

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for High Loop Pile Knitting Machine - High Production Terry Knitting Machine – Morton , The product will supply to all over the world, such as: Senegal, Irish, Florida, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.