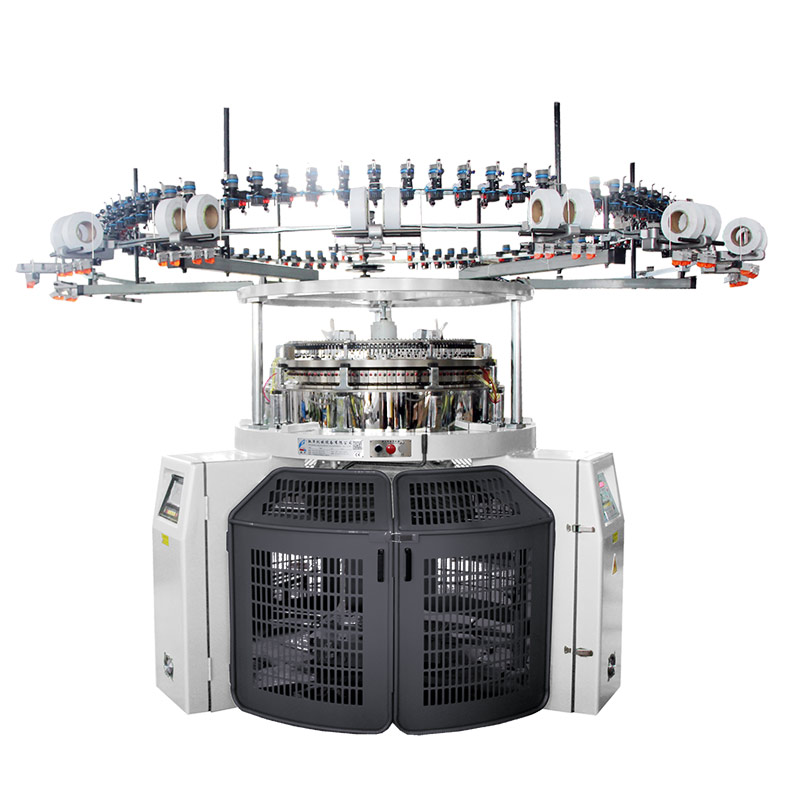

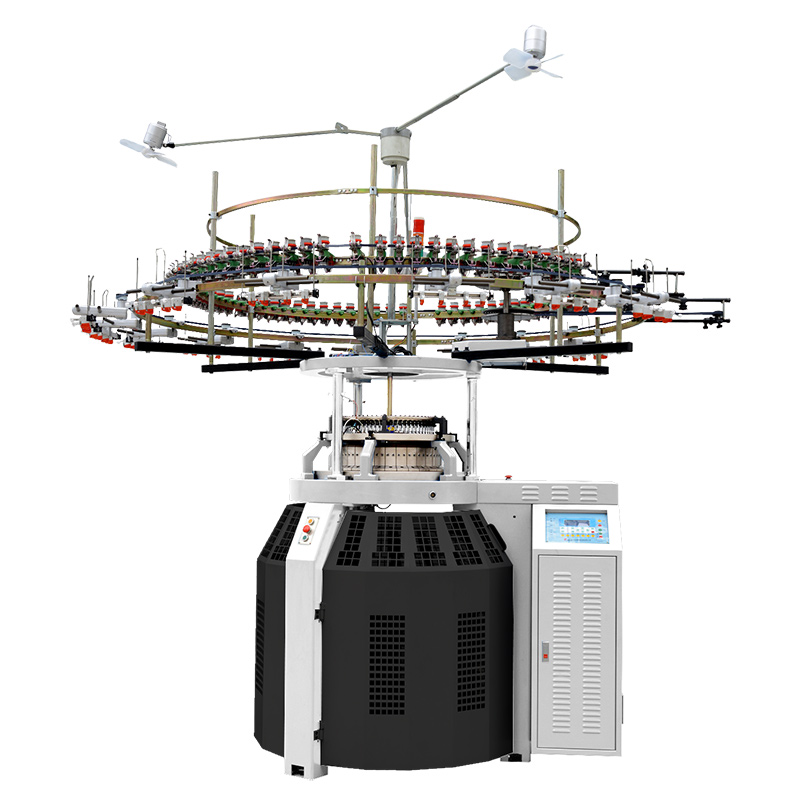

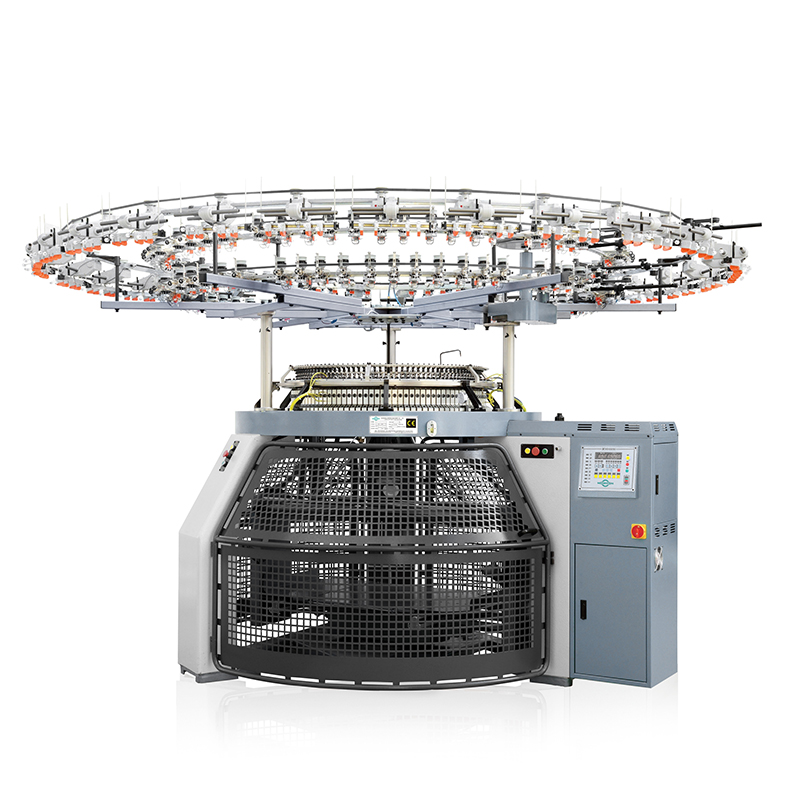

High Loop Pile Knitting Machine - Reverse Terry Knitting Machine – Morton

High Loop Pile Knitting Machine - Reverse Terry Knitting Machine – Morton Detail:

| MODEL | DIAMETER | GAUGE | FEEDER |

| MT-EC-RT2.0 | 30″-38″ | 16G–24G | 60F-76F |

Machine Features:

1. Suspended Wire Race Bearing Design enable the machine improving running precision and ruducing impact resistance.

At the same time, the drive energy consumption is greatly reduced.

2. Using aircraft aluminum aolly on main part of machine to improve heat dissipation performance and reduce force deformation of the cam box.

3. One Stitch Adjustment to replace the visual error of the human eye with machining accuracy, and the accurate scale display with the high-precision Archimedean adjustment makes the replication process of the same cloth on different machines simple and easy.

4. Unique machine body structure design breaks through traditional thinking and improves machine stability.

5. With central stitch system, higher accuracy, simpler structure, more convenient operation.

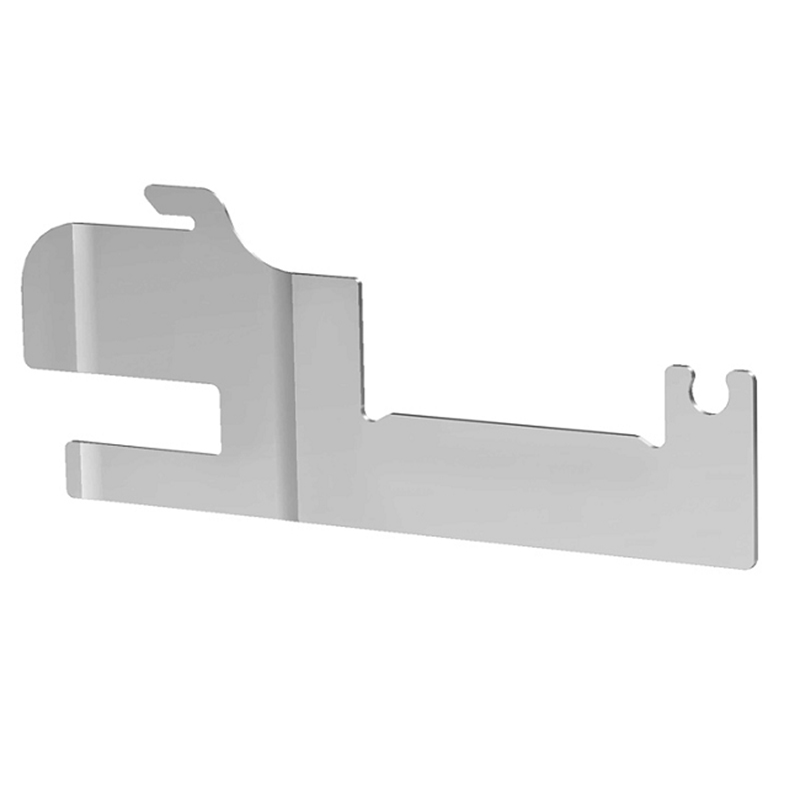

6. New sinker plate fixing design,eliminating deformation of sinker plate.

Product detail pictures:

Related Product Guide:

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for High Loop Pile Knitting Machine - Reverse Terry Knitting Machine – Morton , The product will supply to all over the world, such as: Slovakia, Plymouth, Botswana, Faced with the vitality of the global wave of economic integration, we've been confident with our high-quality items and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

A good manufacturers, we have cooperated twice, good quality and good service attitude.