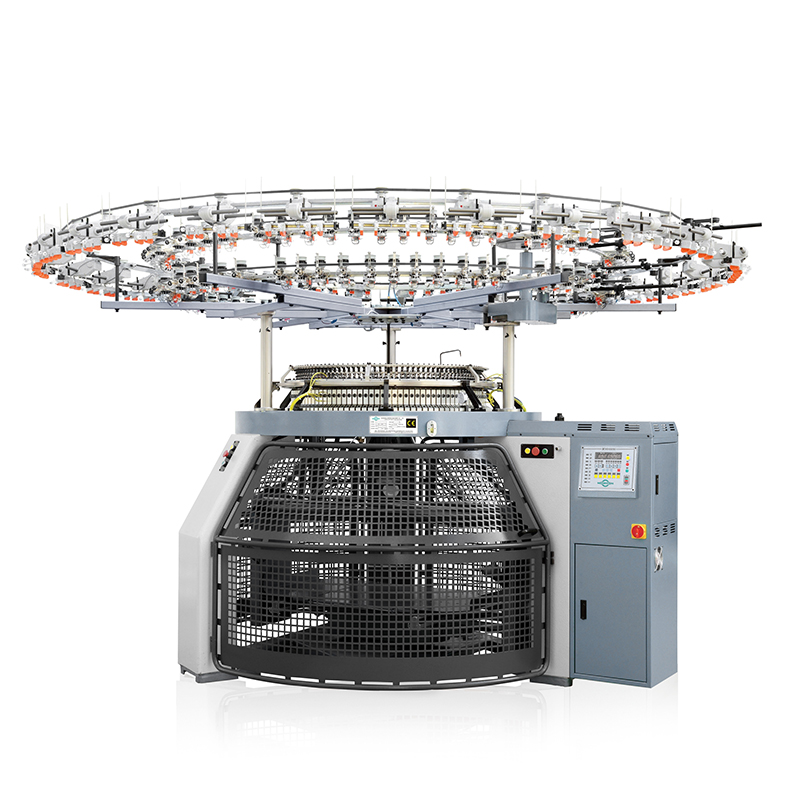

High Production Interlcok Knitting Machine - Reverse Terry Knitting Machine – Morton

High Production Interlcok Knitting Machine - Reverse Terry Knitting Machine – Morton Detail:

| MODEL | DIAMETER | GAUGE | FEEDER |

| MT-EC-RT2.0 | 30″-38″ | 16G–24G | 60F-76F |

Machine Features:

1. Suspended Wire Race Bearing Design enable the machine improving running precision and ruducing impact resistance.

At the same time, the drive energy consumption is greatly reduced.

2. Using aircraft aluminum aolly on main part of machine to improve heat dissipation performance and reduce force deformation of the cam box.

3. One Stitch Adjustment to replace the visual error of the human eye with machining accuracy, and the accurate scale display with the high-precision Archimedean adjustment makes the replication process of the same cloth on different machines simple and easy.

4. Unique machine body structure design breaks through traditional thinking and improves machine stability.

5. With central stitch system, higher accuracy, simpler structure, more convenient operation.

6. New sinker plate fixing design,eliminating deformation of sinker plate.

Product detail pictures:

Related Product Guide:

Assume full accountability to fulfill all demands of our purchasers; attain continual advancements by marketing the advancement of our clientele; grow to be the final permanent cooperative partner of purchasers and maximize the interests of purchasers for High Production Interlcok Knitting Machine - Reverse Terry Knitting Machine – Morton , The product will supply to all over the world, such as: Palestine, Salt Lake City, Greece, Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a "people-oriented, meticulous manufacturing, brainstorm, construct brilliant" organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we've been likely to be pleased to serve you.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.