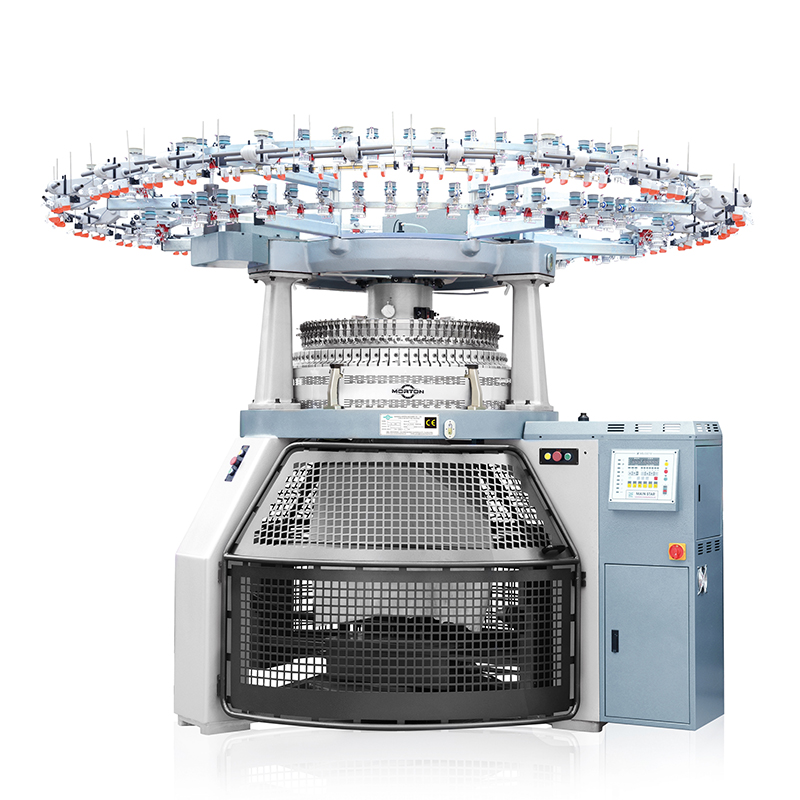

High Speed Rib Circular Knitting Machine - Reverse Terry Knitting Machine – Morton

High Speed Rib Circular Knitting Machine - Reverse Terry Knitting Machine – Morton Detail:

| MODEL | DIAMETER | GAUGE | FEEDER |

| MT-RT2.0 | 30″-38″ | 16G–24G | 60F-76F |

Machine Features:

1. Suspended Wire Race Bearing Design enable the machine improving running precision and ruducing impact resistance.

At the same time, the drive energy consumption is greatly reduced.

2. Using aircraft aluminum aolly on main part of machine to improve heat dissipation performance and reduce force deformation of the cam box.

3. One Stitch Adjustment to replace the visual error of the human eye with machining accuracy, and the accurate scale display with the high-precision Archimedean adjustment makes the replication process of the same cloth on different machines simple and easy.

4. Unique machine body structure design breaks through traditional thinking and improves machine stability.

5. With central stitch system, higher accuracy, simpler structure, more convenient operation.

6. New sinker plate fixing design,eliminating deformation of sinker plate.

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of High Speed Rib Circular Knitting Machine - Reverse Terry Knitting Machine – Morton , The product will supply to all over the world, such as: Atlanta, Azerbaijan, Spain, Our products are mainly exported to Southeast Asia, the Middle East, North America and Europe. Our quality is surely guaranteed. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!