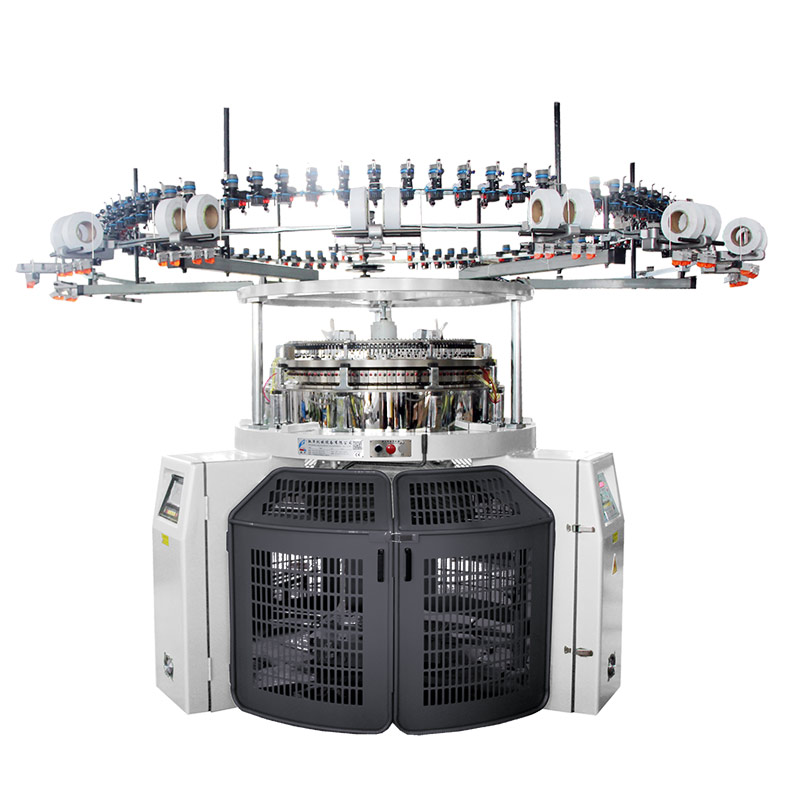

High Speed Single Jersey Open Width Machine - Single Jersey Computerized Jacquard Circular Knitting Machine – Morton

High Speed Single Jersey Open Width Machine - Single Jersey Computerized Jacquard Circular Knitting Machine – Morton Detail:

TECHNICAL INFORMATION

| MODEL | DIAMETER | GAUGE | FEEDER |

| MT-SJ-CJ2.1 | 30″-38″ | 7G–32G | 64F-80F |

Machine Features:

1.3-way computer system with stable operating system.

2.Simple computer system for easy operation and reading of patterns via jacquard controller, quick and effcient.

3.A USB device can be used to easily save and use pattern data.

4.Lower power consumption.

5.Three times quality inspection,implementation of industry certification standards.

6.Lower noise & smooth operation give higher efficiency of operator.

7.Test every order’s material and keep record for check.

8.Parts are all put in stock neatly, stock keeper take notes of all outstock and instock.

9.Take record of every process and worker name, could find person responsible for step.

10.Strictly machine test before delivery for every machine. Report, picture and video will be offered to customer.

11.Professional and high educated technical team, high wear resistant performance, high heat resistant performance.

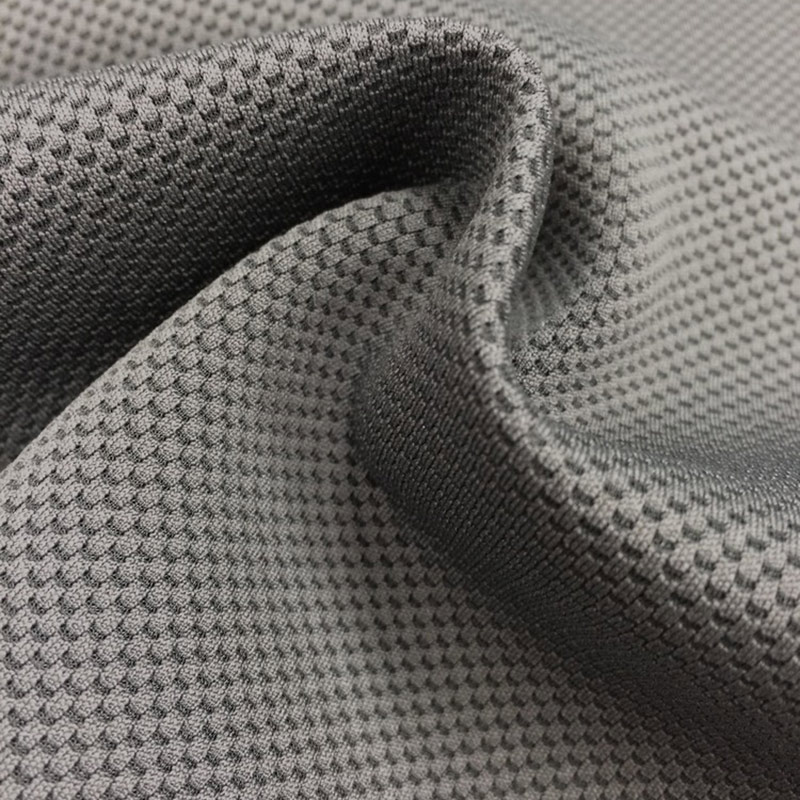

Product detail pictures:

Related Product Guide:

Our firm has been concentrating on brand strategy. Customers' satisfaction is our best advertising. We also offer OEM provider for High Speed Single Jersey Open Width Machine - Single Jersey Computerized Jacquard Circular Knitting Machine – Morton , The product will supply to all over the world, such as: Jordan, Philippines, Peru, Our company is an international supplier on this kind of merchandise. We offer an amazing selection of high-quality products. Our goal is to delight you with our distinctive collection of mindful products while providing value and excellent service. Our mission is simple: To provide the best products and service to our customers at the lowest prices possible.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.