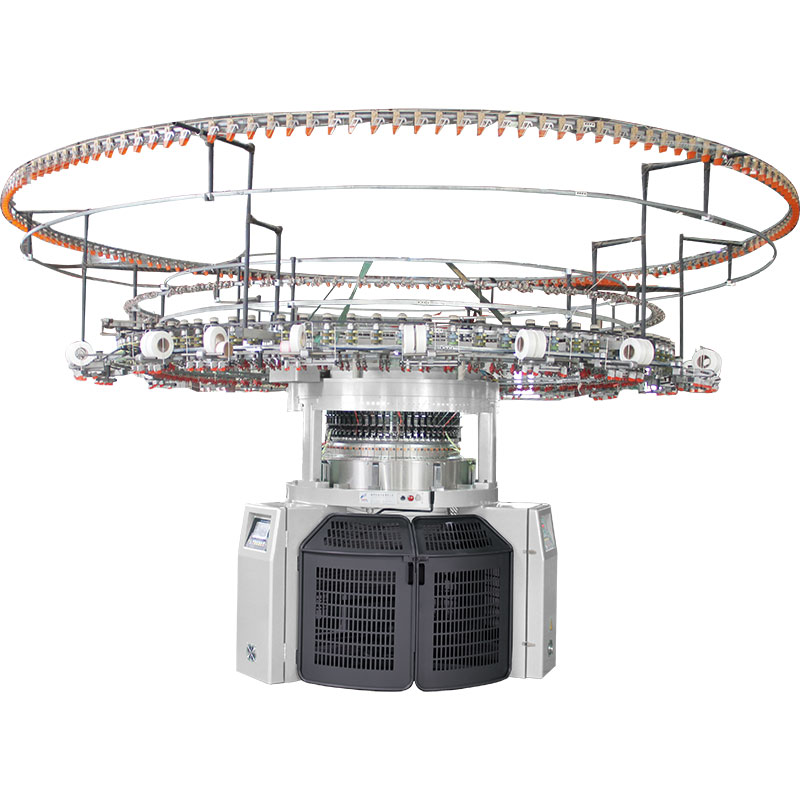

Lycra Stop Motion - Knitting Machine Teeth Belt – Morton

Lycra Stop Motion - Knitting Machine Teeth Belt – Morton Detail:

TECHNICAL FEATURES:

1.Excellent quality belts for circular knitting machine.

2.No noise, anti-satic, oil resistance, heat-resistance.

3.Higher Strength special belt for textile circular knitting machine.

Morton timing belt using unique seamless loop belt technology, the high-strength Kevlar core has strong tensile strength, high fatigue resistance coefficient and no stretching phenomenon.

All imported polyurethane raw materials are selected to ensure high wear resistance of the belt, low noise and maintenance-free.

Morton Tooth belt has high anti-wear ability, high-speed operation stability, and long life. It is suitable for circular knitting machinery in the textile industry, paper industry, and food industry. The product still maintains good operation capacity in high-load transmission. It supports ring connection and can be connected into any length.

WORKING PRINCIPLE OF TIMING BELT:

The timing belt drive is composed of an endless belt with inner teeth on the inner peripheral surface and a pulley with corresponding teeth. During operation, the belt teeth mesh with the tooth groove of the pulley to transmit motion and power. A new type of belt drive with the advantages of transmission and chain drive gear transmission.

Precautions for installation and use of timing belt and timing wheel:

Reduce the center distance of the pulley. If there is a tensioner, it should be loosened first, and then adjust the center distance after installing the belt. For the transmission with fixed center distance, the pulley should be removed first, and then the belt is installed on the pulley, and then the pulley is installed on the shaft to fix it.

Product detail pictures:

Related Product Guide:

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for Lycra Stop Motion - Knitting Machine Teeth Belt – Morton , The product will supply to all over the world, such as: Iraq, Iran, Swansea, We always insist on the management tenet of "Quality is First, Technology is Basis, Honesty and Innovation".We are able to develop new products continuously to a higher level to satisfy different needs of customers.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.