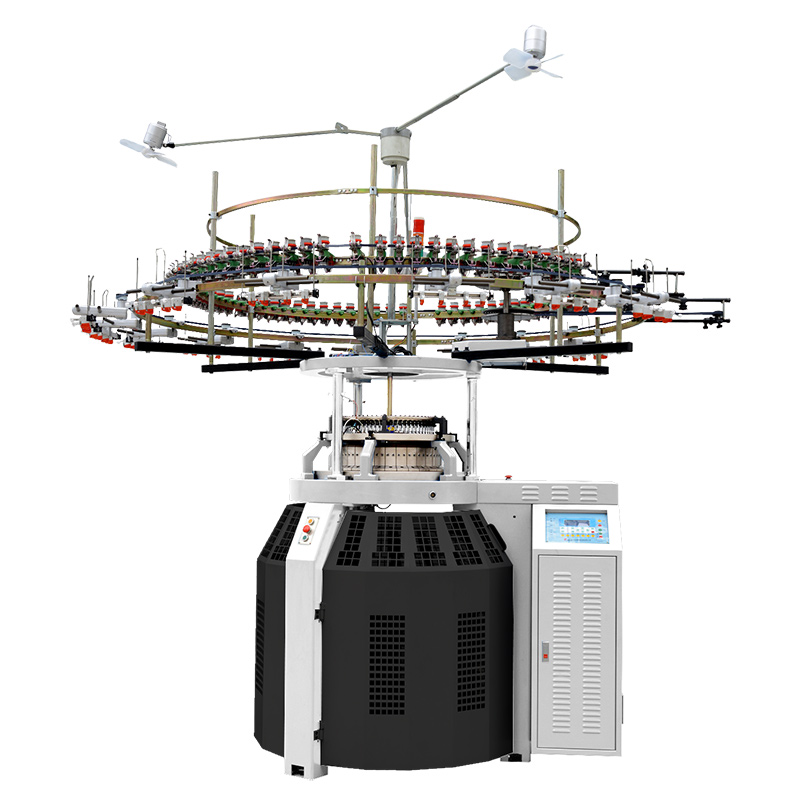

Medical Bandage Knitting Machine

TECHNICAL INFORMATION

| 1 | Product Type | Medical Bandage Knitting Machine |

| 2 | Model Number | MT-MB |

| 3 | Brand Name | MORTON |

| 4 | Voltage/Frequency | 3 Phase,380V/50HZ |

| 5 | Motor Power | 1.5 HP |

| 6 | Dimension(L*W*H) | 2m*1m*2.2m |

| 7 | Weight | 0.65T |

| 8 | Applicable Yarn Materials | Cotton, Polyester,Chinlon,Syntheric Fiber,Cover Lycra etc |

| 9 | Fabric Application | Medial Bandage,Cotton Net Bandage |

| 10 | Color | Black &White |

| 11 | Diameter | 6"-12" |

| 12 | Gauage | 12G-28G |

| 13 | Feeder | 6F-8F |

| 14 | Speed | 60-100RPM |

| 15 | Output | 3000-15000 pcs/24 h |

| 16 | Packing Details | International Standard Packing |

| 17 | Delivery | 30 Days to 45 Days After Receipt of Deposit |

OUR ADVANTAGE:

1.Small profits: Our company's strength, re-credit, keep the contract, to ensure product quality, has won the trust of customers under the principles of various categories and low price. Welcome old and new customers from home and abroad call or come to our company for consultations and negotiations.Consecutive sales increasement of 10 years.

2.Best Service: Customer's satisfaction is always LEADING machinery priority concern, we are keen to solve any problem. We will answer all questions asked, help everyone in need and give response to every prayer.

3. Our professional R&D and QC team can strictly control the product quality to meet your requirement.

4. We offer the best service according to your request, ranging from production, processing to packaging, etc.

FAQS:

1.What are your advantages compared with your competitors?

(1). Qualified Manufacturer

(2). Reliable Quality Control

(3). Competitive Price

(4). High Working Efficiency (24 hours)

(5). One-Stop Service

2.How does your company control quality?

Our dedicated quality inspectors are arranged on our production line to supervise the production and inspect the every details. All products must be inspected before delivery.Inline inspection and final inspection are necessary.

1.All raw material are checked once arriving at our factory.

2.All pieces,logo and other details are checked during production.

3.All packing details are checked during production.

4.All products quality and packing are checked again on final inspection after all installation and test.