Defects along the length of one or more longitudinal directions are called vertical bars.

Common reasons are as follows:

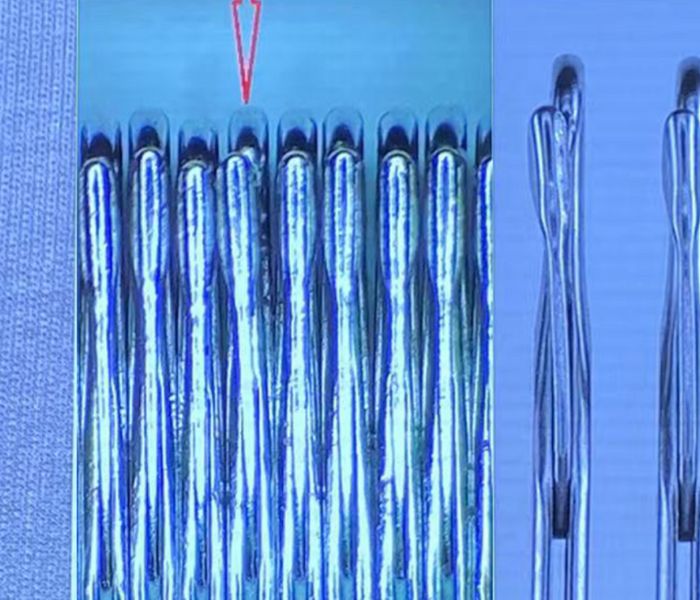

1. Various types of damage to knitting needles and sinkers

The sinker was damaged by the yarn feeder.

Needle latch is bent and skewed.

The needle latch is abnormally cut.

Burrs at the knitting position caused by abnormal contact with the yarn feeder.

Needle hooks stretch due to overload.

2. Knitting needles and sinkers are worn

Accumulation of debris and failure to clean it up in time causes the needle latch to fail to close properly.

Vertical bars caused by corrosion and rust.

Wear at the needle latch pin position.

Wear on the back of the needle bar.

Needle latch wear caused by rough yarns

Sinker ring forming platform wear.

3. Mixing needle or system parts (different type or new/worn)

4. During use, the position of the knitting needle is uneven: the knitting needle is bent, lint accumulates on the back of the knitting needle or sinker, and the cylinder is damaged or worn.

5. Lubrication system problems (knitting needle lubrication failure)

6. Problems in the finishing process

7. Rolling Takedown System pulling problem

Solution:

1. Clean or remove the fibers and dirt accumulated in the needle groove and needle groove.

2. Replace all defective knitting needles (needle bars are bent, damaged or needle tongues are bent, needle hooks are deformed, needle butts are severely worn, etc.)

3. Avoid mixing knitting needles or system components, as well as needles or system components with different operating times.

4.Replace excessively worn cylinder.

Post time: Jan-17-2024