Adjustment method for yarn feeding speed (fabric density)

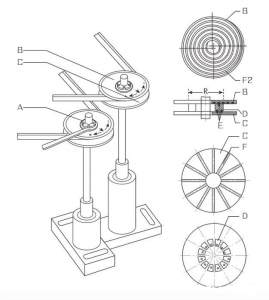

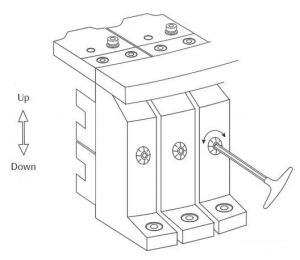

1. Change the diameter of the speed changeable wheel to adjust the feeding speed, as shown in the following figure. Loosen the nut A on the speed changeable wheel and turn the upper spiral adjustment disc B in the direction of “+”. At this time, the 12 internal sliding blocks D will slide outward. As the diameter of the feeding aluminum disc increases, the feeding amount can be increased. Rotate in the direction of “-”, and the 12 sliding blocks D will slide towards the position of the axis. The diameter of the feeding aluminum disc will decrease, and the feeding amount will be reduced. The feeding aluminum disc can be adjusted from 70mm to 200mm in diameter. After adjusting the diameter, lock the upper nut A tightly.

When rotating the upper adjustment plate, try to maintain balance as much as possible to prevent the slider protruding nail E from detaching from the groove (F/F2) in the adjustment plate or slot plate. After adjusting the diameter, please remember to adjust the belt tension.

A: Nut B: Spiral adjusting disc C: Slot disc D: Slider E: Nail F: Slot disc straight groove F2: Adjusting disc spiral groove

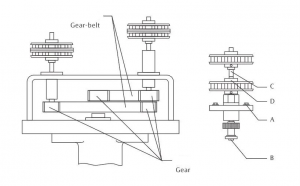

2. Change the gear transmission ratio

If the feeding amount exceeds the adjustment range of the feeding aluminum plate (excessive or insufficient), adjust the feeding amount by changing the transmission ratio by replacing the gear at the lower end of the aluminum plate. Loosen screw A, remove the washer and fix the shaft columns C and D, then loosen screw B, replace the gear, and tighten the nut and four screws A after replacing the gear.

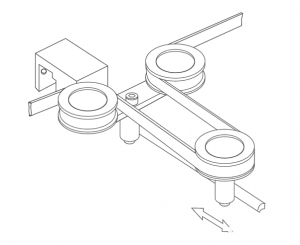

3. Adjusting the tension of the yarn sending belt

Whenever the diameter of the feeding aluminum disc is changed or the gear ratio is changed, the feeding belt must be readjusted. If the tension of the yarn feeding belt is too loose, there will be slipping and yarn breakage between the belt and the yarn feeding wheel, causing losses in weaving. Loosen the fixing screw of the adjusting iron wheel, pull the iron wheel outward to the appropriate tension, and then tighten the screw.

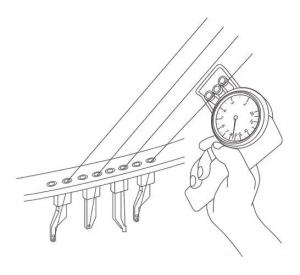

4. After adjusting the yarn feeding speed, the yarn tension will also change accordingly. Rotate the adjustment screw (as shown in the figure below) and use a yarn tensioner to check the tension of each feeding port, adjusting to the desired yarn speed.

Post time: Sep-26-2023