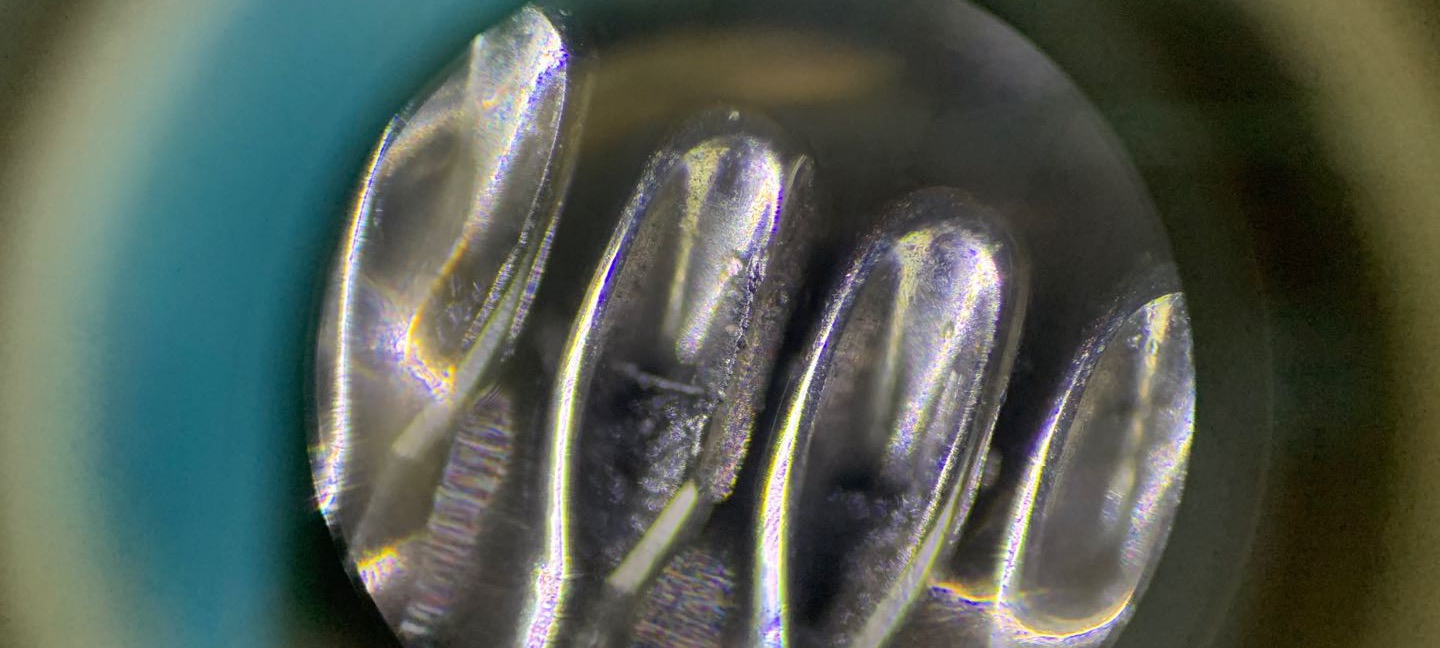

5) Wear on the side of the tongue and spoon

(A) The specifications and models of knitting needles are used improperly, and the thickness is too thick.

(B). The relative position of the upper and lower knitting needles is not correct; if it is a single jersey machine, it is possible that the sinker circle is shifted and the knitting needle hits the sinker.

(C) The lateral swing of the needle tongue of the knitting needle is too large.

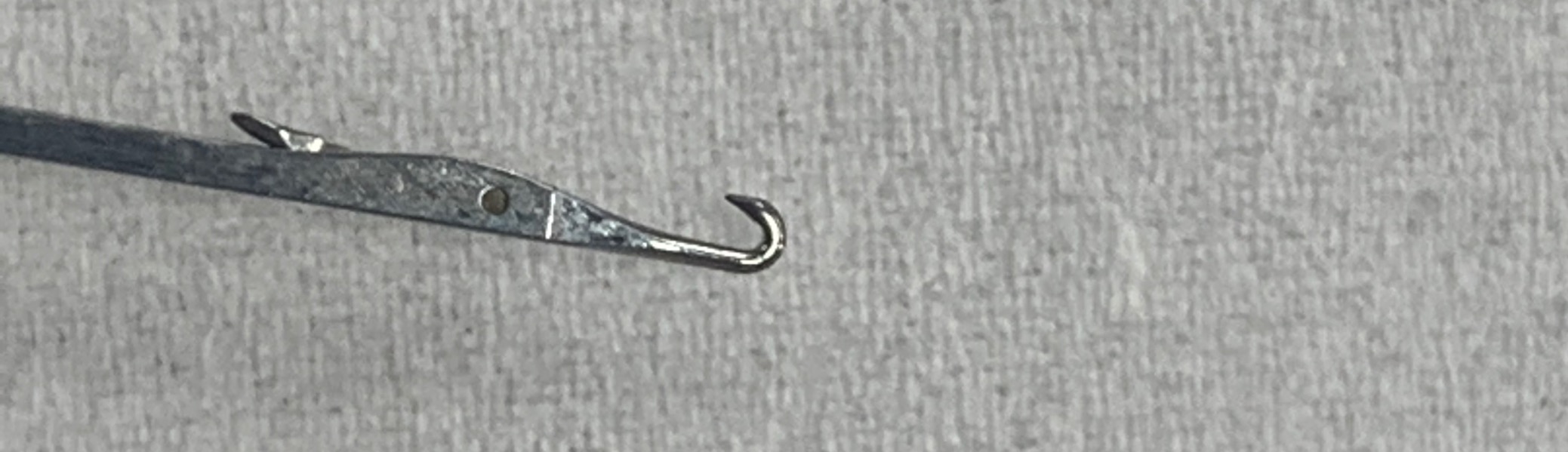

6) Flying needle tongue

(A) Insufficient oil supply of the fuel injector and insufficient lubrication.

(B) Indirectly caused by iron filings due to wear of the Sinker sheet

(C) The yarn contains hard granular impurities or is polluted by dust (D) The environment of the production workshop is poor, and more dust is attached to the machine.

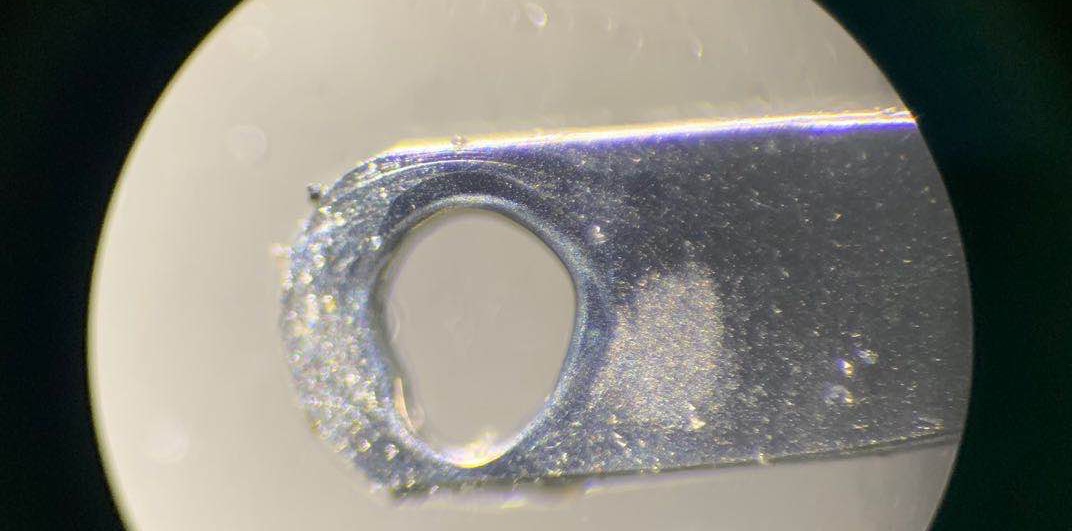

7) Wear on the outside of the hook

(A) The distance between the yarn feeder and the knitting needle is too close to wear.

(B) The gap between the cam of the upper disc and the needle cylinder is too large or the needle guard spring of the needle cylinder of the lower disc is not tight enough, which causes the knitting needles to run and fray to the yarn feeder.

8) Needle groove scoliosis

(A) The combination of knitting needles and needle slips is too loose, and the cam track is too wide (especially the bell mouth of the cam needle is too large), which will cause the knitting needles to swing left and right at the needle position during the movement. Excessive swing may cause this problem.

(B) The needle groove damages the needle groove wall during processing.

(C) The material of the needle itself is defective.

(D). The upper and lower aiming positions are unreasonable (the single jersey machine may cause the counter plate to run out), and the needle and the needle (sheet) are hit.

(E) When the double-sided machine cotton wool is aligned, the flat needle on the upper plate is too out to hit the needle on the lower plate (the flat needle is too out of the lower plate and the needle is out of the upper plate). It may be okay to drive the slow car at the position of the needle entry bell mouth, but it is easy to throw out the corresponding needle when driving fast.

9) The use of knitting needles-the needle tongue cannot be closed for a while or the movement is not flexible

(A) The slot on the back of the needle groove of the knitting needle is too short, and the impurities are not easy to discharge.

(B) The inner wall of the needle groove of the knitting needle is too rough, and it is easy to adhere to grease or fiber cotton.

(C) When weaving high F-number fibers, flying flowers are prone to be produced. Failure to clean up in time causes the flying flowers to be blocked in the needle groove. (It is recommended to use better Sinker to reduce flying flowers)

(D) The quality of the knitting lubricant used is not good or the viscosity of the lubricant is too high, causing the needle tongue to be inflexible or the needle groove to be blocked.

(E) Use poor quality fibers (too much oil and wax) or hydrogen fibers (forked or poor glue quality)

F) The machine has not been maintained for a long time, and the hygiene of the syringe and the dirty core is not in place.

Post time: Jul-13-2021