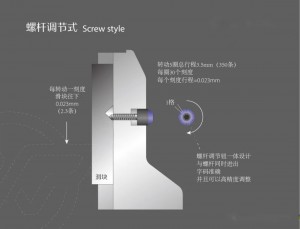

The first type: screw adjustment type

This type of adjusting rod is integrated with the knob. By rotating the knob, the screw drives the adjusting knob in and out. The conical surface of the screw presses the conical surface of the slider, causing the slider and the mountain angle fixed on the slider to move downward.

Applicable: Wide range of application and can be adjusted with high precision.

Advantages: It combines the accuracy of writing and high accuracy, and can satisfy both novices and experts.

Disadvantages: When adjusting the tissue fabric, the different depths of the needles in each path affect the appearance uniformity.

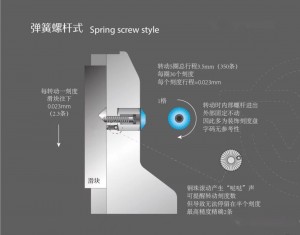

The second type: spring screw type

This type enters and exits by rotating the built-in adjustment rod, and presses the conical surface of the slider through the conical surface of the screw, causing the slider and the mountain angle fixed on the slider to move downward.

Applicable: Wide range of application, can meet medium and high requirements.

Advantages: The appearance is neat and can be adjusted with medium to high precision with the help of sound and flashlight light.

Disadvantages: The adjustment machine master has relatively high requirements, or needs to use a dial indicator. Since it is not an integrated design, the scale and the built-in adjustment rotate separately, and the scale dial is easy to shift, resulting in inaccurate writing.

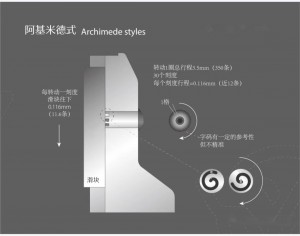

The third type: Archimedean style

In this type, by rotating the adjusting knob, the constant velocity spiral drives the pin on the slider, causing the slider and the mountain angle fixed on the slider to move downward.

Due to structural design reasons, the Archimedean adjustment button has a short stroke, so the movement stroke of each scale slider is relatively large, which is difficult if you encounter a fine needle or a high-demand cloth surface that needs to be accurate to 1-2 wires. Adjustment.

Applicable: Quick coarse adjustment, suitable for producing yarns that are not sensitive to cloth surface, such as cotton yarn.

Advantages: simple and fast, suitable for novices and does not require high requirements for adjusting machine masters.

Disadvantages: The short stroke is difficult to adjust accurately, and the processing difficulty is difficult to produce empty strokes. Reducing the total range of stroke movement, such as reducing the total stroke to 100 lines, can make each scale accurate to 3.3 lines. However, shortening the stroke also reduces the applicable range of the machine.

To sum up, each type of adjustment button has its own advantages and disadvantages. There are only differences in production accuracy, materials and quality between each brand. In principle, there is no absolute good or bad, but should be based on your own Depending on your production needs and personnel situation, choose the type that best suits you.

Post time: Sep-20-2023