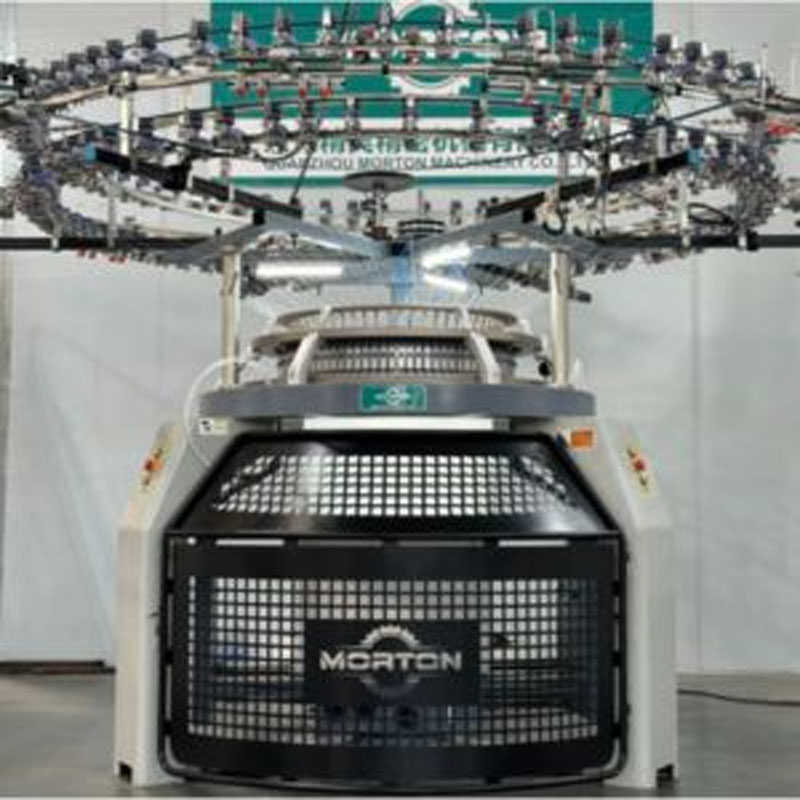

1. Single jersey circular knitting machine

Circular knitting machine, scientific name circular knitting machine (or circular knitting machine). Because circular knitting machine has many loop forming systems , high speed, high output, fast pattern change, good product quality, few processes, and strong product adaptability, it has developed rapidly.

Circular knitting machines are generally divided into two categories: single jersey series and double jersey series. However, according to the types of fabrics (academically called fabrics. Commonly known as grey fabrics in factories), they are divided into the following types.

Single jersey series circular knitting machines are machines with one cylinder. They are specifically divided into the following types.

(1) Ordinary single jersey circular knitting machine. Ordinary single jersey circular knitting machine has many loops (usually 3 to 4 times the diameter of the cylinder, that is, 3 loops 25.4mm to 4 loops/25.4mm). For example, a 30" single jersey machine has 90F to 120F, and a 34" single jersey machine has 102 to 126F loops. It has high speed and high output. In some knitting companies in our country, it is called a multi-triangle machine . Ordinary single jersey circular knitting machine has single needle track (one track), two needle tracks (two tracks), three needle tracks (three tracks), and four needle tracks for one season and six needle tracks. Currently, most knitting companies use four-needle track single jersey circular knitting machines. It uses the organic arrangement and combination of knitting needles and triangles to weave various new fabrics.

(2) Single jersey terry circular knitting machine. It has single-needle, double-needle and four-needle models, and is divided into positive-covered terry machines (the terry yarn covers the ground yarn inside, that is, the terry yarn is displayed on the front side of the fabric, and the ground yarn is covered inside) and positive-covered terry machines (that is, the terry fabric we usually see, the ground yarn is on the back side of the fabric). It uses the arrangement and combination of sinkers and yarns to weave and produce new fabrics.

Single jersey terry circular knitting machine

(3)Three thread fleece knitting machine. The three-thread fleece machine is called fleece machine or a flannel machine in knitting enterprises. It has single-needle, double-needle and four-needle models, which are used to produce various types of velvet and non-velvet products. It uses knitting needles and yarn arrangement to produce new fabrics.

Three thread fleece knitting machine.

2. The difference between single jersey and double jersey knitting circular machinesThe difference between 28-needle and 30-needle looms: Let's take a look at the principle of the loom first.

Looms are divided into warp knitting and weft knitting. Warp knitting mainly uses 24 needles, 28 needles, and 32 needles. Weft knitting includes double-sided thread machines with 12 needles, 16 needles, and 19 needles, weft knitting double-sided large circular machines with 24 needles, 28 needles, and 32 needles, and weft knitting single-sided large circular machines with 28 needles, 32 needles, and 36 needles. Generally speaking, the lower the number of needles, the smaller the density of the knitted fabric and the narrower the width, and vice versa. A 28-needle warp knitting machine means that there are 28 knitting needles per inch of needle bed. A 30-needle machine means that there are 30 knitting needles per inch of needle bed. A 30-needle machine is more delicate than a 28-needle loom.

Post time: Jul-23-2024