In recent years, regenerated cellulose fibers (such as viscose, Modal, Tencel, etc.) have appeared continuously to meet people’s needs in a timely manner, and also partially alleviate the problems of today’s lack of resources and the destruction of the natural environment.

Due to the dual performance advantages of natural cellulose fibers and synthetic fibers, regenerated cellulose fibers are being widely used in textiles on an unprecedented scale.

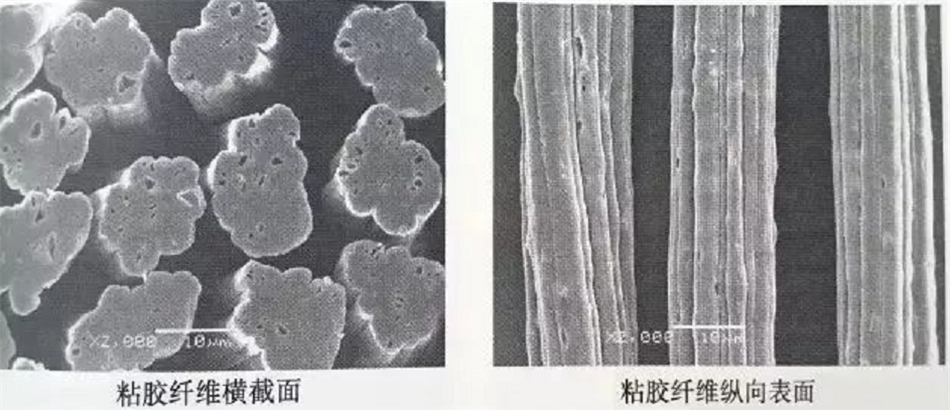

Ordinary viscose fiber

Viscose fiber is the full name of viscose fiber. It uses “wood” as a raw material, and is a cellulose fiber obtained by extracting and remodeling fiber molecules from natural wood cellulose.

The inhomogeneity of the complex molding process of ordinary viscose fibers will make the cross-section of conventional viscose fibers be waist-round or irregular, with holes inside and irregular grooves in the longitudinal direction. Viscose has excellent hygroscopicity and easy dyeing, but its modulus and strength are low, especially low wet strength.

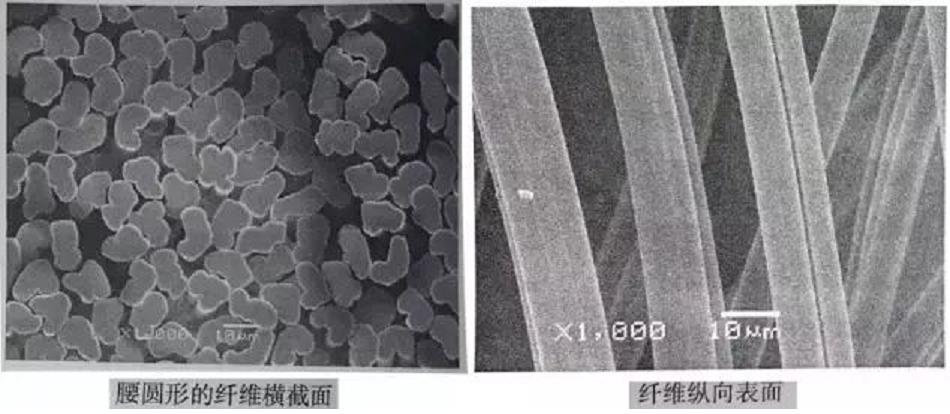

Modal fiber

Modal fiber is the trade name of high wet modulus viscose fiber. The difference between it and ordinary viscose fiber is that modal fiber improves the shortcomings of low strength and low modulus of ordinary viscose fiber in the wet state. It also has high strength and modulus in the state, so it is often called high wet modulus viscose fiber.

The structure of the inner and outer layers of the fiber is relatively uniform, and the skin-core structure of the fiber cross-section is not as obvious as that of ordinary viscose fibers. Excellent.

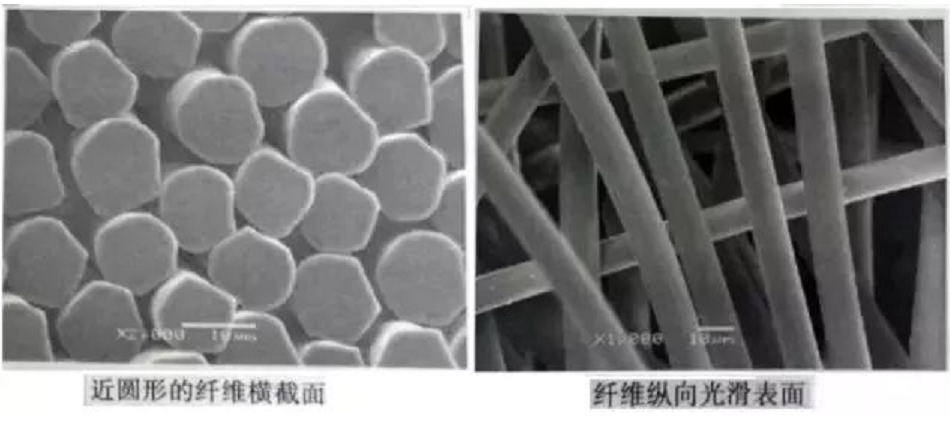

Lyocell fiber

Lyocell fiber is a kind of man-made cellulose fiber, which is made of natural cellulose polymer.

The morphological structure of lyocell fiber is completely different from that of ordinary viscose. The cross-sectional structure is uniform and round, and there is no skin-core layer. The longitudinal surface is smooth without grooves. It has better mechanical properties than viscose fiber, good washing Dimensional stability , with high hygroscopicity. Beautiful luster, soft touch, good drapability and good flow.

Fiber characteristics

Viscose fiber

It has good hygroscopicity and meets the physiological requirements of human skin. The fabric is soft, smooth, and has good air permeability. spinning performance. The wet modulus is low, the shrinkage rate is high and it is easy to deform.

Modal fiber

Soft touch, bright and clean, bright color, good color fastness, especially smooth fabric feel, bright cloth surface, better drape than existing cotton, polyester, viscose fiber, with the strength and toughness of synthetic fiber, with silk The same luster and hand feel, the fabric has wrinkle resistance and easy ironing, good water absorption and air permeability, but the fabric has poor stiffness.

Lyocell fiber

It has a variety of excellent properties of natural fibers and synthetic fibers, natural luster, smooth hand feeling, high strength, basically no shrinkage, and good moisture permeability, good air permeability, soft, comfortable, smooth and cool, good drape, durable and durable.

Scope of application

Viscose fiber

Short fibers can be spun purely or blended with other textile fibers, suitable for making underwear, outerwear and various decorative items. Filament fabrics are light in texture and can be used for quilt cover and decorative fabrics in addition to being suitable for clothing.

Modal fiber

Modal knitted fabrics are mainly used to make underwear, but also used in sportswear, casual wear, shirts, advanced ready-to-wear fabrics, etc. Blending with other fibers can improve the poor stiffness of pure modal products

Lyocell fiber

Covering all fields of textile, whether it is cotton, wool, silk, hemp products, or knitting or weaving fields, high-quality and high-end products can be produced.

Post time: Nov-04-2022