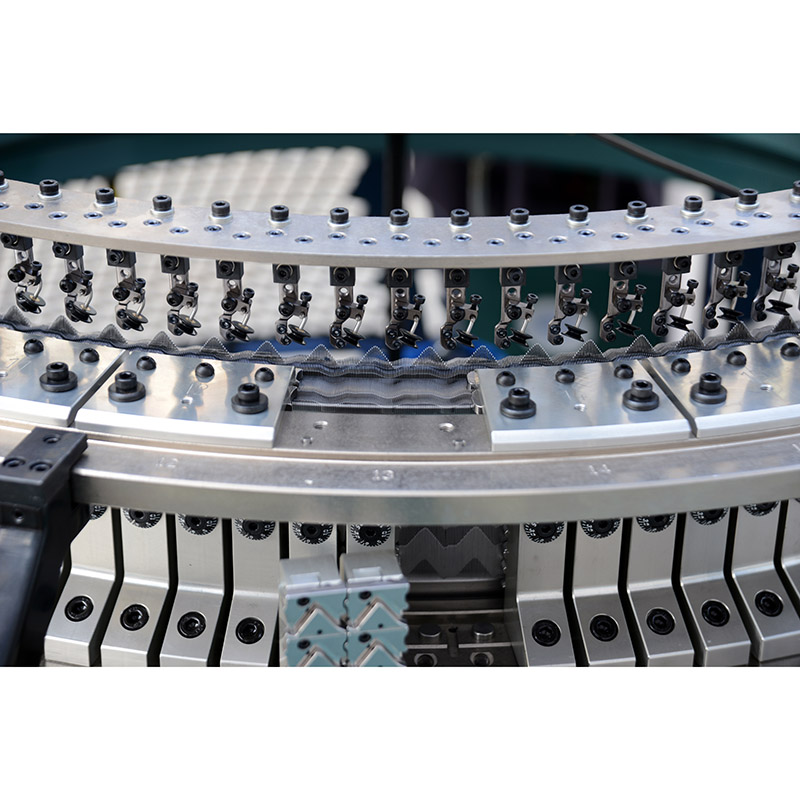

Top Suppliers High Speed Rib Circular Knitting Machine - High Production Terry Knitting Machine – Morton

Top Suppliers High Speed Rib Circular Knitting Machine - High Production Terry Knitting Machine – Morton Detail:

| MODEL | DIAMETER | GAUGE | FEEDER |

| MT-TY2.0 | 30″-38″ | 16G–24G | 60F-76F |

Machine Features:

1 Suspended Wire Race Bearing Design enable the machine improving running precision and ruducing impact resistance.

At the same time, the drive energy consumption is greatly reduced.

2 Using aircraft aluminum aolly on main part of machine to improve heat dissipation performance

and reduce force deformation of the cam box.

3 One Stitch Adjustment to replace the visual error of the human eye with machining accuracy,

and the accurate scale display with the high-precision Archimedean adjustment makes the

replication process of the same cloth on different machines simple and easy.

4 Unique machine body structure design breaks through traditional thinking and improves machine stability.

5 With central stitch system, higher accuracy, simpler structure, more convenient operation.

6 New sinker plate fixing design,eliminating deformation of sinker plate.

Morton Single Terry Machine Interchange Series can be interchanged to single and three-thread fleece machine by replacing the conversion kit.

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for Top Suppliers High Speed Rib Circular Knitting Machine - High Production Terry Knitting Machine – Morton , The product will supply to all over the world, such as: European, Barcelona, Atlanta, To work with an excellent items manufacturer, our company is your best choice. Warmly welcome you and opening up the boundaries of communication. We are the ideal partner of your business development and look forward to your sincere cooperation.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.